Technology

Understanding the constructive needs of the beneficiaries with regard to their uniforms and workwear is translated into a careful design stage of the patterns and data processing by use of information technology.

Understanding the constructive needs of the beneficiaries with regard to their uniforms and workwear is translated into a careful design stage of the patterns and data processing by use of information technology.

We use the Optitex design system which insures the digitization, grading and printing of the patterns on an A0 before cutting the pieces to their size for assembly.

For our Romanian private customers from the defence field we have implemented on our online shop a complex dynamic size-rendering system which turns results depending on the specificities of the wearer, so that from the very design stage we insure our clients of an optimal fit for their products.

The technological processes we use cover all the stages of manufacturing the end-product:

Pre-production:

- design

- CAD

- sampling

- sourcing

Production:

- cutting

- stitching

- seam sealing

- trimming

Post-production:

- labeling

- quality control

- packing

- individual delivery

Emphasis on product quality is found in the internal procedures for quality control, our equipment being checked in several stages: of cut pieces, before and after assembly and 100% final quality check, piece by piece.

The Invictus® brand is sustained by investments in new technologies and modernization by means of the

The Invictus® brand is sustained by investments in new technologies and modernization by means of the

Structural Funds for 2015 which will bring important benefits to improve the efficiency of our internal processes:

- DESIGN: integrated CAD system with laser cutting technology

- DEVICES: embroidery and seam-sealing machines, other specific devices

- PRODUCTION LINE: for ceremonial or corporate-wear suits

- LABORATORY: for testing fabrics and accessories

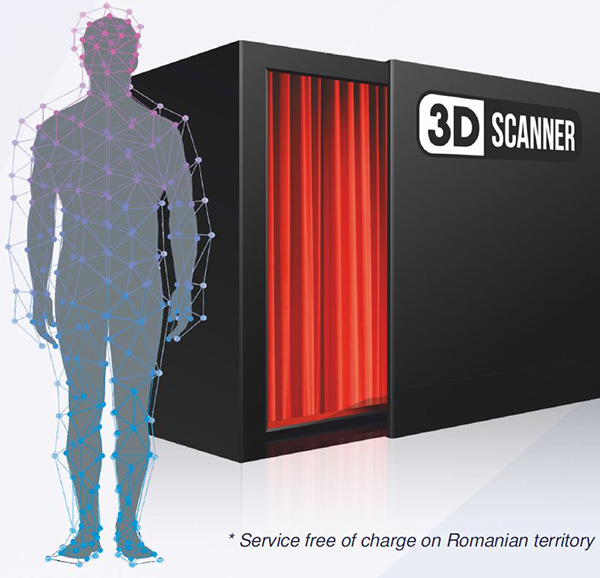

The technological advancement we offer to our Romanian* beneficiaries consists of a highly performant system for customization of a product by the use of 3D technology.

The technological advancement we offer to our Romanian* beneficiaries consists of a highly performant system for customization of a product by the use of 3D technology.

The system is based on a mobile individual chamber for tridimensional scanning of the human body, capable of recognizing and registering a very high number of constituent points which generate dimensions in the form of individual measures which later allow the data to be processed by the CAD system to generate custom tailoring hence an optimal fit of the end-product.

* Service available for Romanian territory.